Garage Concrete Polishing Detroit, MI

Transform your garage in Detroit, MI, with professional concrete polishing services , turning a mundane and dusty area into a stunning and long-lasting space. Our specialty lies in grinding, honing, and polishing existing concrete floors to create striking and resilient surfaces that stand out.

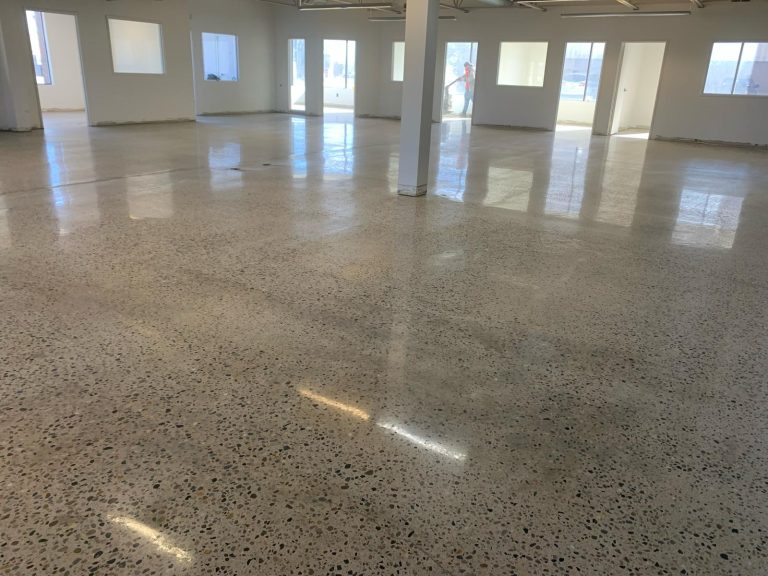

Our skilled team utilizes advanced floor polishing equipment and techniques to deliver a range of finishes, from a soft satin sheen to a brilliant high-gloss shine. Understanding the specific needs of a garage environment, we offer customized solutions that improve both its functionality and aesthetics.

Opting for polished concrete flooring in your garage comes with numerous advantages, such as resistance to oil stains, chemical spills, and the wear and tear from heavy foot and vehicle traffic. This type of flooring is remarkably durable and simple to maintain, making it an ideal choice for workshops, storage, or even finished garage spaces.

We are dedicated to providing top-notch craftsmanship and outstanding customer service, ensuring that your garage makeover will surpass your expectations. Moreover, we can add stained concrete options to personalize your garage flooring and reflect your unique style.

Polished Concrete Garage Floor

Imagine enhancing the utility and visual appeal of your Detroit, MI home with a sleek polished concrete garage floor. This contemporary flooring solution can elevate a practical area into a welcoming and well-organized environment.

We excel in creating stunning and resilient polished concrete floors tailored to withstand the rigors of garage use. Our cutting-edge polishing techniques allow us to achieve a range of finishes while effectively removing any existing coatings during the preparation phase.

Polished concrete floors come with numerous benefits, including their ability to resist damage from vehicles and accidental drops. They also demand very little upkeep, requiring just a quick sweep and mop to maintain their pristine appearance.

Transitioning to a polished concrete garage floor can greatly enhance both the functionality of your space and the overall value of your home. Trust us to assist you throughout the transformation journey, from the initial preparation stage to the final sealing and resurfacing options.

Garage Concrete Polishing

Your garage is far more than just a parking spot for your vehicle; it’s a dynamic area brimming with potential. Homeowners can reimagine it for various uses, whether as a storage area, a DIY workshop, a comfortable gathering place, a creative hobby zone, or even a home office. It has the capacity to serve multiple functions beyond simply housing your car.

Revitalize your garage from a bland area into a welcoming environment by opting for a sleek polished concrete floor. As comprehensive concrete specialists, Our company specializes in offering customized garage flooring solutions that cater to your specific needs. If you envision a specific look or functionality for your garage, we are here to turn that vision into reality.

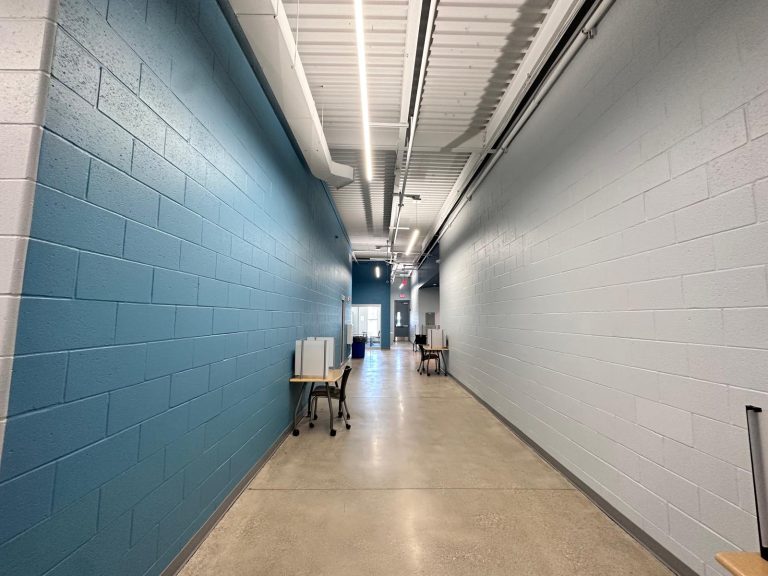

We believe that achieving a stunning polished floor doesn’t mean sacrificing strength and resilience. Polished concrete is a favored choice for flooring in various establishments, including educational institutions, healthcare facilities, industrial sites, and commercial buildings, thanks to its durability and aesthetic appeal.

Garage Polished Concrete Benefits

Protection And A Spill-Resistant Floor

This type of flooring enhances the grip for rubber tires, machinery, and foot traffic. Unlike vinyl or laminate, polished concrete floors are highly resistant to a variety of chemicals, solvents, and other liquids that may be spilled. Damage occurs only from extremely corrosive substances. However, additional protective measures can be applied through specialized coatings and additives to further enhance the floor’s durability.

Resilience And High Durability

Our coatings provide a polished, stain-resistant, and non-porous surface. With minimal maintenance, concrete emerges as the optimal choice for durability. It effectively withstands wear and tear from everyday use, remaining intact even under heavy foot traffic. Polished concrete maintains its integrity for years with just occasional cleaning, and it can endure the operation of forklifts and other moderately heavy equipment without sustaining damage.

Chemical Resistance And Slip Resistance

While concrete surfaces can become slippery, especially in wet conditions or areas prone to spills, applying a non-slip coating can enhance safety by adding texture to prevent slips and falls. Additionally, sealing concrete with a chemical-resistant epoxy coating can protect against harsh chemicals and corrosion, though it’s worth noting that unsealed concrete is porous.

Aesthetically Pleasing

There are numerous polished concrete flooring styles to choose from, allowing you to create the desired aesthetic for your garage. The polish can offer a range of finishes, from subtle matte to high-gloss reflective surfaces. Concrete can be tailored to suit your specifications, and many polished concrete options come in a variety of colors and textures that stand out. With proper installation, even custom vinyl or tile can resemble polished concrete.

Environmental Sensitivity

If environmental conservation is important to you, polished concrete floors are an excellent choice. Concrete, in its simplest form, is made from plentiful natural resources like stone, sand, and water. When it’s time to remove the floor, there are no harmful chemicals or volatile organic compounds present, and it is recyclable. Many polished concrete options also comply with LEED certification standards.

Hygienic

Sealing and finishing concrete helps it resist liquids, including water, effectively. Coatings can create waterproof barriers that prevent contaminants from penetrating the concrete. Some concrete coatings even offer antimicrobial protection. Additionally, a well-finished concrete floor should be free of cracks or crevices that could harbor food particles, dirt, or bacteria.

The Levels Of Polished Concrete: A Comprehensive Guide

Here’s how we execute our 400 Grit Polish procedure:

- Eliminate any old adhesives, such as tile mastic and carpet glue, from the surface.

- Repair and patch any visible cracks as necessary.

- Grind the floor with diamond grits of 30, 80, and 120.

- Transition to 50 grit and grind the floor again.

- Polish the floor using 100, 200, and ultimately 400 grit resins.

- Conclude the process at the 400-grit resin bond to achieve a subtle low-sheen finish.

- Results in a low-luster matte appearance with minimal reflection visible from about 100 feet away.

- Optionally, you can add color and a densifier.

- Carefully hand-polish the edges of the walls for accuracy.

- Apply two coats of sealer for protection.

- Burnish the floor to reach a glossy finish.

- Achieves a low-sheen result with a soft matte look.

Here’s our approach to the 800 Grit Polish process:

- We utilize diamond abrasives of 800-grit or higher to achieve a superior sheen compared to a level 2 finish.

- To begin, we eliminate any leftover adhesives, such as tile mastic or carpet glue, from the flooring.

- Next, we address and repair any cracks that require attention.

- We initiate the process by grinding the floor with 30-grit diamonds to enhance the surface quality.

- This is followed by further grinding with 80-grit and 120-grit diamonds for additional refinement.

- We then polish the floor using a series of resins: 50, 100, 200, 400, and ultimately, 800 grit to ensure a smooth finish.

- This technique results in excellent light reflectivity, with clear reflections of side and overhead lighting visible from 30 to 50 feet away.

- As an optional enhancement, we can apply color and densifier to boost both aesthetics and durability.

- For a detailed touch, we hand-polish the edges of the walls.

- We finish by applying two coats of sealer.

- Finally, we burnish the floor to achieve a glossy, visually appealing finish.

- The result is a surface with significantly enhanced sheen and improved light reflectivity.

Here’s our detailed guide for achieving a 1500 Grit Polish:

- We start by using resin pads of 1500 grit or above to enhance the surface quality.

- Initially, we eliminate any adhesives, including tile mastic and carpet glue.

- We then address and repair any cracks that require attention.

- The process begins with grinding the floor using 30-grit diamonds to refine the surface.

- Next, we continue the grinding process with 120-grit diamonds for further refinement.

- The floor is polished using a sequence of 200, 400, 800, and finally 1500 grit resins to achieve a sleek finish.

- This process enhances the shine and clarity of the floor, resulting in a semi-polished look.

- Optionally, we can incorporate color and a densifier to improve both aesthetics and durability.

- For a meticulous finish, we hand-polish the edges of the walls.

- Two coats of sealer are then applied to protect the surface.

- Finally, we burnish the floor to create a glossy and visually appealing finish.

- Reflections on the surface will appear sharper and clearer, though not as defined as those achieved at higher grit levels.

Here’s how we achieve the 3000 Grit Polish:

- We start with 3000-grit resin-bond diamond pads or utilize a high-speed burnisher equipped with specialized buffing pads.

- Initially, we eliminate any leftover adhesives, such as carpet glue and tile mastic.

- Next, we address and repair any cracks present on the surface.

- The grinding process begins with diamond grits of 200.

- The floor is then polished using resins in the grits of 400, 800, 1500, and ultimately 3000, resulting in a sleek finish.

- This process yields a glass-like appearance with a mirror-like finish.

- It offers an exceptional shine with complete clarity, enabling clear reflections of surrounding objects.

- For added enhancement, color and densifier can be applied. We also perform hand polishing on the wall edges for meticulous detailing.

- From different angles, the floor has a wet look.

- We then apply two coats of sealer.

- The floor is burnished to achieve a high-gloss finish.

- The final stage of the polishing process ensures that the surface achieves optimal gloss and a silky smooth texture.

- Concrete is polished using specialized grinding machines to remove any impurities.

- If necessary, cracks and blemishes are repaired with a suitable patching compound.

- Additional grinding with finer diamond tools may be conducted depending on the intended finish and the condition of the floor.

- Once the grinding is complete, the surface is meticulously cleaned.

- If desired, a stain can be applied, providing a range of choices from subtle neutrals to bold colors.

- The surface is then sealed with a topical sealer that meets the specific needs of the project and the objectives for the floor, with extra layers added for softer or more porous concrete.

- The grind, stain, and seal method is faster than traditional mechanical polishing.

- We begin by using our industrial diamond grinder to grind the surface until the upper layer is sufficiently removed for the best adhesion of the sealer.

- Our aim is to remove the old, unattractive surface, revealing a fresh and clean base ready for staining and sealing.

- We provide a variety of sealer options tailored to the floor’s location and usage. If you choose to stain, we first apply the stain and then follow up with a sealing coat.

- Check out our online selection of colors available for staining.

- It’s essential to understand that bypassing the refinement stage with higher diamond counts may result in visible uniform swirls, which is a compromise for saving time and costs.

FAQ's

Yes, we can definitely polish a concrete garage floor! Our team specializes in transforming garage floors with high-quality polishing techniques that enhance both the appearance and durability of the concrete. We can help you achieve a sleek, professional finish that adds value to your space.

Although polished concrete floors are resistant to oils and other spills, they may not withstand repeated exposure to brake fluid or gear oil. For hobbyist mechanics, a flake epoxy floor is an ideal choice for garage flooring.

Polished concrete can be an excellent choice for a garage. It is durable, low maintenance, and resistant to stains, chemicals, and heavy traffic. The smooth, reflective surface can also brighten the space by reflecting light. Additionally, polished concrete floors are so easy to clean and can be customized with many colors & finishes to match your aesthetic preferences.

The cost to polish a garage concrete floor typically ranges from 3-12 dollars per square foot. The price can vary based on the given factors:

- Condition of the existing concrete

- Size of the garage

- Level of finish

- Location

To get an accurate estimate, it’s best to contact our contractors for quotes tailored to your specific project.

A polished concrete floor can provide slip resistance in both wet and dry conditions. In some cases, it may even be more slip-resistant than resinous flooring systems.