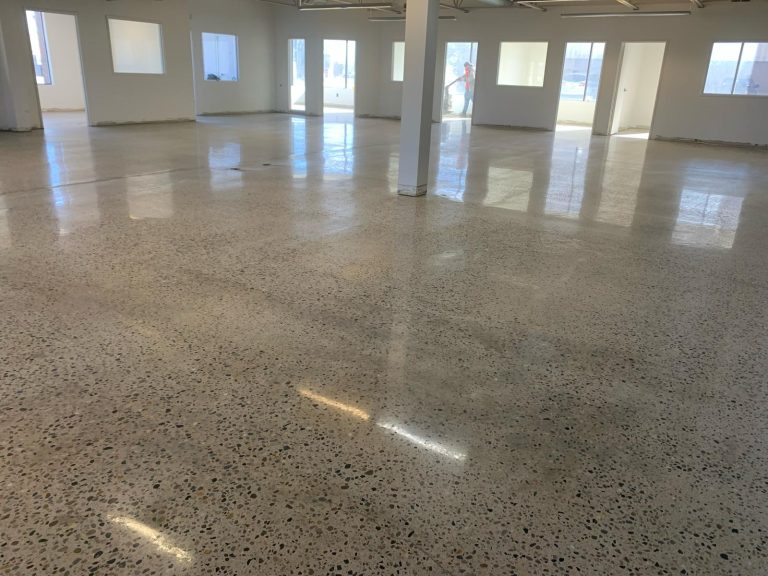

Basement Concrete Polishing Detroit, MI

Revamp your Detroit, MI basement into an appealing, practical space with our professional concrete polishing service. Using our state-of-the-art polishing equipment, we specialize in transforming lifeless, unfinished concrete into a beautiful, low-maintenance surface.

Our skilled team understands the specific challenges associated with basement flooring. We offer tailored solutions to improve your home’s functionality and value. We also provide comprehensive project estimates, ensuring clarity and client satisfaction throughout the process.

By choosing us for your basement’s polished concrete, you’ll benefit from a moisture-resistant, durable floor that is easy to clean. This flooring option is ideal for a variety of purposes, such as playrooms, home gyms, and completed living areas. We guarantee top-notch quality and service from start to finish.

Basement Concrete Polishing

Keeping basement floors clean and in good condition can be challenging, mainly since they are often used for storage. Spills, leaks, and heavy items can damage the floor, leading to cracks in the concrete. Fortunately, Polished Floors provides a solution with durable epoxy-coated floors. This glossy coating makes your floor safe and slip-resistant and protects it from oil, solvents, acids, and common household chemicals.

We are leaders in modern concrete design. Our specially crafted polished concrete floors meet the highest standards of exclusivity and durability. With many years of experience in polished concrete, our highly trained team has extensive expertise in residential and commercial settings.

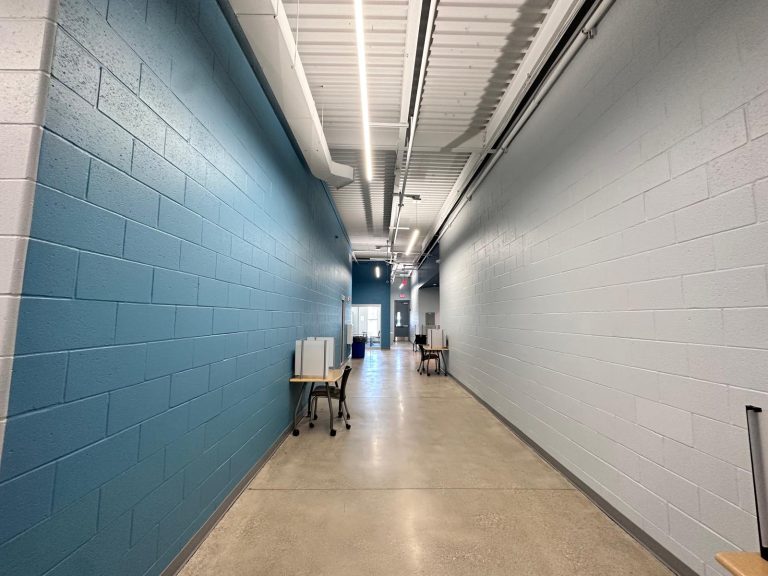

Polished Concrete Basement Floor

Transform your basement into a chic, welcoming living area with a sleek, polished concrete floor. Located in Detroit, MI, our company utilizes cutting-edge floor polishers to create a variety of stunning finishes that enhance the overall aesthetic of your home.

Polished concrete is highly resistant to moisture, making it an ideal option for below-ground spaces. This flooring solution is simple to clean and maintain and represents a valuable investment that can enhance both the usable square footage and the overall value of your home.

Take advantage of our free estimate to discover how a polished concrete floor can enhance the functionality of your basement. We manage every aspect of the process, from preparation to the final seal, ensuring our services are fully customized to meet your specific requirements.

Our Floor Polishing Process

Our concrete polishing service is completely dust-free, ensuring a clean and eco-friendly experience. This means you can enjoy the polishing process without the concern of airborne dust particles. Our team of specialists utilizes a carefully selected range of grit levels to achieve the perfect smoothness and shine, delivering results that are sure to impress you.

Using advanced machinery that works similarly to wood sanding, we grind the concrete to reach your desired matte or glossy finish. The grit level of our diamond pads is specifically chosen to match the level of shine you’re looking for. Our method of dry concrete polishing eliminates the need for water, allowing us to polish the surface to your specifications before sealing it for a lasting finish.

These are the finishes we offer:

- Cream Polished Concrete

- Non-exposed Aggregate (No exposure)

- Salt & Pepper Finish (Medium Exposure)

- Full Aggregate Exposure (Full Exposure)

Why Concrete Floor Polishing Shouldn't Be Attempted as a DIY Project?

To protect your basement or garage floor from potential damage during a DIY project, it’s best to leave it to the professionals. Our skilled contractors have the expertise required to grind, stain, and polish your concrete floors effectively, ensuring a high-quality finish.

Polishing can transform any concrete floor, but the final results will largely depend on the condition of the existing slab. Rustic concrete floors have gained immense popularity in residential and commercial renovations in recent years, and for good reason. Most slabs can be polished to create a stunning rustic aesthetic that often comes at a lower cost than traditional hardwood, offering remarkable durability and requiring minimal upkeep.

Count on us, proud to serve the Midwest region, to elevate the shine of your floors. We also prioritize your safety by offering slip-resistant quartz epoxy floor coatings for your basement, further enhancing the functionality and appeal of your space.

Benefits of Polished Concrete for Your Basement

Let’s take a closer look at the valuable benefits that polished concrete floors offer, including the following:

Affordable

Polished concrete offers a sleek, high-end look while remaining budget-friendly. Its initial price per square foot is on par with affordable options like carpeting, but its overall cost tends to be lower in the long run.

Durable

One of the standout features of polished concrete is its remarkable strength and resilience, making it ideal for industrial settings such as manufacturing and warehouses. Its solid nature allows it to handle extensive foot traffic and heavy loads from machinery without issue.

Long Lasting

When it comes to longevity, polished concrete floors are tough competitors. Proper installation and maintenance can last over a hundred years, far outlasting common flooring materials like vinyl, laminate, and carpet.

Environmentally Friendly

Polished concrete is an environmentally responsible choice. Its installation process does not require harmful chemical treatments or adhesives, and it promotes energy efficiency, enhancing its appeal as a flooring option.

Low maintenance

Caring for polished concrete floors is straightforward. Unlike other flooring options that require regular stripping and waxing, these floors are low-maintenance. They resist dirt and dust accumulation and need only occasional mopping to keep them looking great.

Non-slip

While polished concrete may seem slick, a non-slip epoxy coating can easily mitigate this concern. This treatment adds the necessary texture to enhance safety, ensuring the surface remains secure and slip-resistant when properly applied.

Factors To Consider When Choosing Polished Concrete

Polished concrete is a popular flooring option due to its diverse applications in various settings. It is particularly effective for residential basements, helping prevent moisture and mold buildup.

With its modern and elegant appearance, polished concrete enhances a space’s overall ambiance. Its versatility makes it a practical choice for a wide range of environments.

Basement polished concrete stands out among various flooring options due to its numerous benefits, making it a popular selection for basements and other areas within buildings. Its durability and aesthetic appeal are key factors contributing to its widespread use.

Whether you’re looking for a bold design that captures attention or a more understated look for relaxation, we offer a range of style choices. Our polished concrete solutions not only enhance the visual appeal of your basement but also feature a non-slip surface that helps minimize the risk of accidents.

Before making a final decision on flooring, it’s essential to consider the local climate and environmental conditions. Understanding these factors can help you choose the flooring that best suits your needs and enhances your space.

Our team of concrete floor polishing experts is dedicated to revitalizing your dull basement floor and restoring its luster regardless of your location. Contact us today to discover how we can assist you with your flooring projects.

A straightforward surface can significantly enhance your life, whether you transform your basement into extra living quarters, a storage area, or a fitness zone. Our polyurea and polyaspartic basement floor coatings offer an excellent choice for those seeking a hassle-free flooring solution. They allow for easy clean-ups of spills and make it simple to sweep or vacuum away debris. You can bring your floor back to its original, pristine condition with just a non-corrosive cleaner!

If you have a damp basement, it’s crucial to ensure that every part of the area stays dry, as mold and mildew can quickly become problematic. Our top-of-the-line coatings effectively seal concrete surfaces, helping to prevent spills, flooding, and leaks. By blocking excessive moisture from seeping into your home’s concrete foundation, these coatings are vital in preserving your foundation’s integrity.

Each team member undergoes comprehensive training before joining us, ensuring that you can rely on us to collaborate with some of the leading basement polished concrete companies in Michigan.

Conventional concrete slabs often struggle to withstand the harsh chemicals, pressure, and movements that lead to cracks and deterioration in basement floors over time. We significantly enhance the surface’s durability and visual appeal by employing our comprehensive multi-step process of grinding, smoothing, and polishing.

Our concrete polishing services utilize top-of-the-line tools and techniques to achieve a superior finish for your floors.

Our process involves using a high-powered concrete polishing machine that effectively grinds your floor to create a flat, reflective surface.

Once we complete the installation, your floors will look sophisticated and practically brand new.

Enhancing polished concrete with a color or stain is an effective way to elevate its appearance. Our team is here to assist you in coordinating your flooring with the color palettes of your other properties. We offer premium concrete staining services in various shades to suit your needs.

We utilize durable and non-reactive concrete dyes, allowing them to penetrate any surface layer seamlessly. Regardless of your location within our service area, you can trust us to deliver exceptional coloring services. Our selection of stains comes in a wide array of hues.

In addition to applying a single-color dye, our company specializes in creating unique designs for polished flooring to cater to your specific preferences.

If you’re searching for experts in concrete floor grinding, you’ve come to the right place.

Basement floors often encounter issues due to environmental factors and general wear over time, making them potentially hazardous to navigate. Our services address cracks, dents, and uneven areas in your concrete flooring. After our grinding and smoothing process, your floor will be safe, smooth, and crack-free.

Every concrete polishing project starts with ensuring the surface is level. Our experienced team is equipped to address any irregularities in your concrete floor, preventing further damage and enhancing its appearance.

The Levels Of Polished Concrete: A Comprehensive Guide

Here’s how we perform our 400 Grit Polish process:

- Eliminate old adhesives such as tile mastic and carpet glue from the surface.

- Repair and fill in any cracks as needed.

- Grind the floor with diamond grits of 30, 80, and 120.

- Switch to a 50-grit diamond and grind the floor again.

- Polish the surface using 100 and 200 resin grits, then finish with 400 grit.

- Stop at the 400-grit resin bond to achieve a matte finish with a subtle luster.

- Results in a low-gloss matte appearance with minimal reflection visible from about 100 feet away.

- Optionally, color and densifier can be applied.

- Carefully hand-polish the edges of the walls for a neat finish.

- Apply two coats of sealer for protection.

- Burnish the surface to obtain a shiny finish.

- This process yields a low-sheen finish and a subtle matte look.

Execution of the 800 Grit Polish Process:

- We begin the process by utilizing an 800-grit diamond abrasive or finer to achieve a superior sheen to a level 2 finish.

- The first step is to remove any leftover adhesives from the flooring, such as tile mastic or carpet glue.

- Next, we address any visible cracks that require repair and patch them adequately.

- Start the grinding process with 30-grit diamonds to enhance the surface.

- Progress with further grinding using 80-grit and 120-grit diamonds for a more refined finish.

- For polishing, we employ 50, 100, 200, 400, and ultimately, 800 grit resins to ensure a polished, smooth surface.

- This method yields excellent light reflectivity, allowing clear side and overhead lighting reflections from 30 to 50 feet away.

- We can apply color and a densifier to boost the floor’s aesthetic and durability.

- For a meticulous finish, we hand-polish the edges of the walls.

- Finally, we apply two coats of sealer for protection.

- To complete the process, we burnish the floor, resulting in a glossy and appealing finish.

- This approach achieves a surface with a significantly higher sheen and enhanced light reflectivity.

Here’s our step-by-step guide for achieving a 1500 Grit Polish:

- We use resin pads with a grit of 1500 or finer to refine the surface further.

- The initial step is eliminating adhesives, including tile mastic and carpet glue.

- Address and repair any cracks that require attention.

- Begin by grinding the floor with 30-grit diamonds to enhance the surface.

- Next, continue grinding with 120-grit diamonds to achieve a finer surface finish.

- We use 200, 400, 800, and ultimately, 1500 grit resin pads to create a smooth and refined surface for polishing.

- This process enhances the shine and clarity of the floor, resulting in a semi-polished look.

- If desired, we can add color and a densifier to improve appearance and durability.

- Carefully hand-polish the edges of the walls for meticulous finishing details.

- Apply two coats of sealer for added protection.

- Finally, burnish the floor to attain a glossy and attractive finish.

- Reflected objects will appear sharper and more precise, though not as distinct as with higher grit levels.

Here’s our refined process for achieving a 3000 Grit Polish:

- We use a 3000-grit resin-bond diamond or a high-speed burnisher with specialized buffing pads.

- Remove any existing adhesives from the surface, including carpet glue and tile mastic.

- Address and repair any cracks that may be present.

- Start grinding the floor with diamond grits at 200.

- Progressively polish the floor using resin grits of 400, 800, 1500, and finally 3000 for a flawlessly smooth finish.

- This technique results in a mirror-like appearance, similar to glass.

- Achieves a brilliant shine with exceptional clarity, allowing for clear reflections of surrounding objects.

- Color and densifier can be applied to enhance the surface.

- Carefully hand-polish the edges of the walls for meticulous detailing.

- The finished floor is wet when viewed from different angles.

- Apply two coats of sealer to protect the surface.

- Burnish the floor to create a glossy finish.

- The final polishing phase ensures the surface achieves maximum gloss and smoothness.

- Specialized grinders are used to polish concrete, effectively removing any contaminants present on the surface.

- Any cracks or divots in the concrete are repaired using a patching compound as necessary.

- Depending on the condition of the floor and the desired look, additional grinding with finer diamond tools may be performed for a smoother finish.

- Once the grinding is complete, the surface undergoes a thorough cleaning process.

- To enhance the appearance, a stain in various shades, from neutral to bold hues, can be applied.

- A topical sealer customized to meet the project’s requirements and the flooring’s goals is applied, with extra coats recommended for softer or more porous concrete surfaces.

- Grinding, staining, and sealing is faster than a complete mechanical polish.

- We grind the surface with an industrial diamond grinder until we have sufficiently removed the top layer, ensuring optimal adhesion for the sealer.

- Our aim is to remove the old, unattractive surface, resulting in a fresh, clean base ready for staining and sealing.

- We provide a variety of sealer options tailored to your floor’s location and use. If you choose to stain, we apply it and follow it up with a sealing coat.

- Check out the online selection of colors we offer for your staining choices.

- Remember that skipping the refinement step with higher diamond counts can result in noticeable uniform swirls, which is a compromise for saving time and costs.

FAQ's

Polishing basement concrete floors can transform them into sleek, modern spaces with enhanced durability. At GetPro, we start by removing any coatings or imperfections and repairing cracks or joints with epoxy fillers. We then grind the concrete with progressively finer diamond tools to achieve a smooth, shiny finish. After applying a chemical densifier for added durability, we polish the surface to a glossy finish and may apply a sealer for extra protection. Trusting professionals like GetPro ensures a high-quality, durable, and attractive polished concrete floor.

Epoxy flooring tends to be more costly than polished concrete because of its complex installation process and extensive customization options.

To smooth a concrete basement floor, we first clean the surface and repair any cracks or holes. Next, we grind the concrete with diamond abrasives, starting with coarse grit and moving to finer grits for a smoother finish. Low spots are filled with a self-leveling compound, which is then polished after drying. Finally, the surface is cleaned, and a sealer can be applied for added protection. For the best results, professional assistance is recommended, especially for large projects.

To enhance the look of your concrete basement floor, start by thoroughly cleaning the surface and repairing any cracks or holes. Choose a finishing method: polish the concrete for a high-gloss finish, apply an epoxy coating for a sleek, durable surface, or use concrete stain or paint for added color. Consider adding decorative elements like area rugs or mats for extra warmth and style. Finally, seal the surface to protect and maintain its appearance. These steps can turn your basement floor into a visually appealing and functional space.

Polishing a concrete basement floor is generally not considered a DIY project due to the specialized equipment and expertise required. It involves several steps, including grinding, densifying, and polishing, each requiring specific tools and techniques to achieve a high-quality finish. Additionally, the process demands careful preparation and attention to detail to ensure a durable and aesthetically pleasing result. For these reasons, hiring a professional with experience in concrete polishing is often the best approach to achieving the desired outcome.

Polished concrete floors offer several benefits for basements:

- Durability

- Aesthetic Appeal

- Low Maintenance

- Customization

- Increased Lighting

- Safety

- Design Flexibility

Polishing concrete not only improves its functionality but also adds an elegant touch to your basement space.

Yes, basement humidity can affect polished concrete, though it generally resists moisture well. High humidity might trap moisture beneath the surface, causing issues like peeling or bubbling. It can also interfere with the curing process, leading to a less smooth finish, and may promote mold growth. Regular maintenance, proper ventilation, and using dehumidifiers can help protect against these issues. Ensuring the concrete is properly sealed and the subfloor is well-prepared can also mitigate humidity-related problems.