Commercial Concrete Polishing Detroit, MI

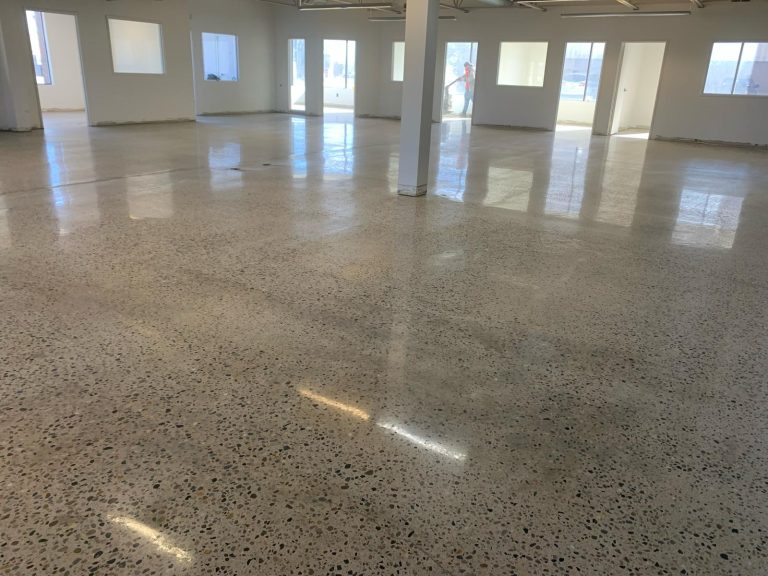

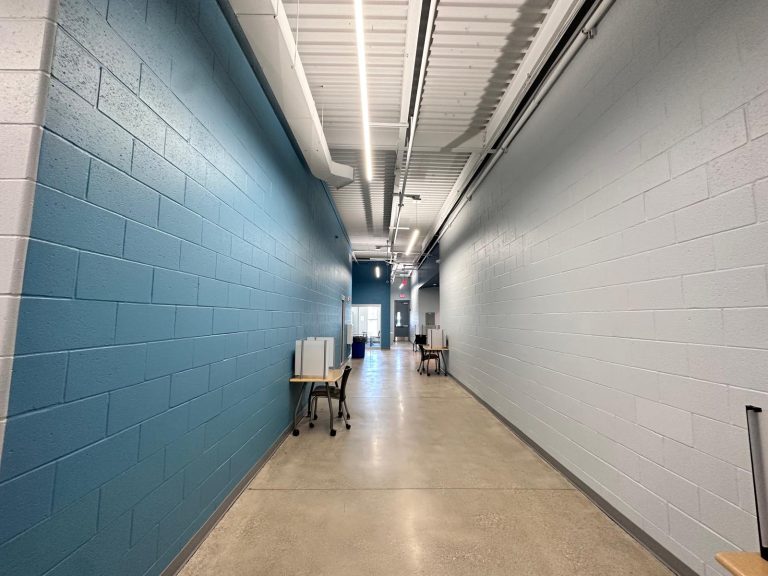

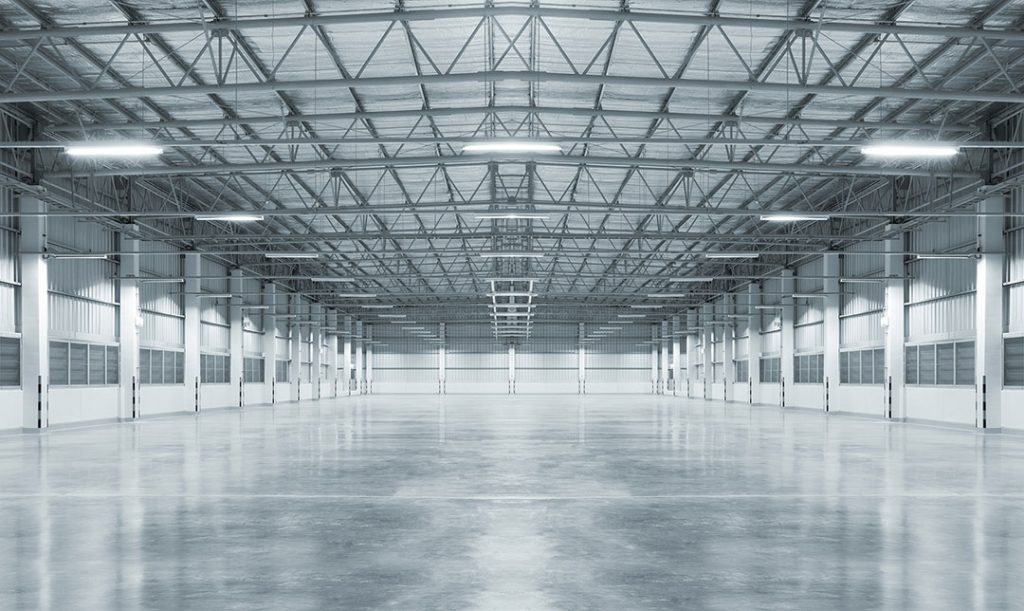

Located in Detroit, MI, our company is dedicated to delivering top-notch commercial concrete polishing services designed to improve both the durability and visual appeal of your business floors. We understand the distinct requirements of various commercial settings, including retail outlets, showrooms, office spaces, and warehouses.

Our skilled team employs cutting-edge floor polishing methods and state-of-the-art equipment to revitalize dull concrete, resulting in sleek, resilient, and low-maintenance surfaces. We pride ourselves on providing outstanding service, which includes offering detailed cost estimates for each project to maintain transparency and ensure client satisfaction.

The commercial concrete polishing procedure we follow involves mechanically grinding the existing concrete floors to achieve the desired level of smoothness and aggregate exposure. This process is complemented by honing and polishing with increasingly finer abrasives, culminating in a robust and dense surface that can withstand heavy foot traffic, resist stains, and endure daily wear and tear.

We provide a wide range of finishes, from a subtle satin sheen to an eye-catching high-gloss shine. Furthermore, we can incorporate stained concrete finishes that align with your brand’s aesthetic, guaranteeing that you receive flooring solutions that are not only durable and functional but also visually striking.

Commercial Polished Coatings

We specialize in offering commercial polished coatings in Detroit, MI, designed to enhance the protection and customization of your concrete floors. While polished concrete is celebrated for its strength, the addition of specialized coatings can greatly bolster its resistance to chemicals, wear, and impacts, making it ideally suited for bustling commercial spaces.

We offer a variety of high-performance coating options, including epoxy and polyurethane, which can be seamlessly applied over polished concrete to fulfill your unique performance and aesthetic requirements. We prioritize transparency by providing detailed estimates for all coating applications, ensuring you can make well-informed decisions.

Our commercial polished coatings can be customized with a range of colors and stains, allowing you to align your floors with your brand identity or interior design vision. The seamless and resilient characteristics of these coatings not only facilitate easy cleaning and maintenance but also promote a professional and hygienic environment for your business.

Commercial Concrete Floor Refinishing Service

We offer a professional concrete floor refinishing service in Detroit, MI, designed to rejuvenate concrete surfaces that have suffered from wear, stains, or damage over time. We understand that maintaining a polished look is essential for businesses, and our refinishing solutions can help restore your floors to their former elegance.

Utilizing advanced floor polishing equipment and restoration methods, our team effectively removes blemishes, fixes cracks and chips, and re-polishes your concrete to achieve a stunning and long-lasting finish. Our team conducts comprehensive evaluations and offers transparent cost estimates for all refinishing projects, ensuring you are informed every step of the way.

Our commercial concrete floor refinishing service serves as an economical alternative to complete floor replacements, significantly reducing downtime and minimizing disruption to your business activities. Furthermore, we can add decorative staining or protective sealants to enhance both the appearance and durability of your newly refinished floors. Our skilled team is dedicated to delivering exceptional results that highlight your commercial space at its finest.

Commercial Polished Concrete

We specialize in expert concrete polishing services that deliver a robust and long-lasting finish for commercial flooring. Our solutions are particularly beneficial for expansive commercial environments, serving as a budget-friendly substitute for conventional concrete flooring options. With a focus on versatility, our concrete polishing techniques are designed for a wide range of commercial and industrial settings, guaranteeing both durability and visual attractiveness. We proudly extend our concrete polishing services to various types of commercial establishments:

- Office Buildings

- Manufacturing Facilities

- Retail Stores

- Showrooms

- Warehouses

- And more!

The Levels Of Polished Concrete: A Comprehensive Guide

Here’s how we carry out our 400 Grit Polish process:

- Eliminate any old adhesives from the surface, such as tile mastic and carpet glue.

- Address and repair any visible cracks as necessary.

- Start the grinding process using diamond grits of 30, 80, and 120.

- Transition to 50 grit for an additional grinding session.

- Polish the surface with 100, 200, and then finish with 400 grit resins.

- Conclude the process using the 400-grit resin bond to achieve a subtle low-sheen finish.

- This technique results in a matte look with minimal reflections noticeable from around 100 feet away.

- Optionally, color and a densifier can be added to enhance the outcome.

- Carefully hand-polish the edges near the walls for accuracy.

- Apply two coats of sealer for enhanced protection.

- Burnish the floor to create a glossy finish.

- This yields a soft matte appearance with a low-sheen effect.

Here’s our approach to the 800 Grit Polish process:

- We utilize diamond abrasives rated at 800-grit or finer to achieve a finish that exceeds a level 2 sheen.

- The process starts with the removal of any remaining adhesives, like tile mastic or carpet glue, from the flooring.

- Following that, we conduct an inspection and make necessary repairs to any cracks.

- To enhance the surface quality, we commence by grinding the floor with 30-grit diamond abrasives.

- This initial grinding is succeeded by further refinement with 80-grit and 120-grit diamonds.

- Next, we polish the floor using a sequence of resin grits: 50, 100, 200, 400, and ultimately, 800 grit, ensuring a pristine finish.

- This technique provides excellent light reflectivity, allowing for clear images of nearby and overhead lighting, visible from 30 to 50 feet away.

- As an optional enhancement, we can apply color and a densifier to elevate both the aesthetics and durability of the surface.

- For precise detailing, we hand-polish the edges along the walls.

- We wrap up the process by applying two coats of sealer.

- In the final step, we burnish the floor to achieve a glossy and visually impressive finish.

- The outcome is a surface that demonstrates a significantly improved sheen and enhanced light reflectivity.

Here’s our all-inclusive guide to achieving a 1500 Grit Polish:

- We begin by using resin pads rated at 1500 grit or above to enhance the surface quality.

- Initially, we eliminate any adhesives such as tile mastic or carpet glue.

- Following that, we assess and repair any cracks that require attention.

- The process kicks off with grinding the floor using 30-grit diamond abrasives to prepare the surface.

- Next, we move to the grinding phase with 120-grit diamonds for further refinement.

- Polishing the floor is performed methodically with 200, 400, 800, and ultimately 1500 grit resin pads to achieve a polished finish.

- This technique boosts the floor’s shine and clarity, resulting in a semi-polished look.

- Additionally, we can incorporate color and a densifier to enhance both appearance and durability.

- For a meticulous finish, we hand-polish the edges near the walls.

- After that, we apply two coats of sealer to protect the surface.

- Finally, we burnish the floor to create a glossy and appealing finish.

- The reflections on the surface will be clearer and sharper, though not as pronounced as those achieved with higher grit levels.

Here’s our refined 3000 Grit Polish procedure:

- We kick off the process with either 3000-grit resin-bond diamond pads or a high-speed burnisher combined with specialized buffing pads.

- First, we remove any lingering adhesives, such as carpet glue and tile mastic.

- Next, we carefully inspect the surface for cracks and perform any necessary repairs.

- The grinding phase begins with diamond grits starting at 200.

- Following that, we polish the floor using resins in stages of 400, 800, 1500, and ultimately 3000 grit to achieve a smooth, luxurious finish.

- The outcome is a stunning, glass-like mirror surface.

- The floor will reflect light beautifully, showcasing sharp reflections of nearby objects.

- As an optional enhancement, we can apply a color treatment and densifier. We also take the time to hand-polish the edges of the walls for meticulous detailing.

- From various perspectives, the floor appears to have a wet look.

- We proceed to apply two coats of sealer for added protection.

- The final step is burnishing the floor to amplify its glossy sheen.

- By completing the polishing process, we ensure that the surface reaches its peak gloss and smoothness.

- Concrete is polished using advanced grinding machinery to remove any surface irregularities.

- If needed, any cracks or imperfections are repaired using suitable patching materials.

- Additional grinding with finer diamond tools can be carried out depending on the desired aesthetic and the state of the floor.

- Once the grinding is complete, the surface is meticulously cleaned.

- If desired, a stain can be applied, providing a range of choices from understated neutrals to bold hues.

- The surface is then treated with a sealer that meets the project’s specific needs and desired outcomes for the flooring, with extra layers applied for softer or more porous concrete.

- The grind, stain, and seal method is more efficient compared to traditional mechanical polishing techniques.

- We begin the process with our industrial diamond grinder, which effectively grinds the surface and removes enough of the top layer to promote strong adhesion for the sealer.

- Our objective is to remove the old, unattractive surface, revealing a fresh and clean foundation that’s ready for staining and sealing.

- We provide a variety of sealer options tailored to the specific requirements and usage of your flooring. If you choose to stain, we first apply the stain followed by a top sealing coat.

- Check out our online selection of stain colors available for your choice.

- It’s essential to understand that bypassing the refinement stage with higher diamond counts may result in visible swirls, which is a compromise for saving time and costs.

Our Experience

As your dedicated contractor for commercial concrete polishing and grinding, we excel in not just the installation of a variety of flooring options and finishes but also in the grinding and polishing of both newly poured and existing concrete floors. Our grinding process effectively removes old adhesives and rectifies any flaws in the concrete slab.

By polishing concrete floors, we can enhance the shine to match your specific desires. Whether you prefer a subtle matte or satin finish suitable for certain spaces or a high-gloss shine that stands out in others, we can customize the outcome to fit your vision. Furthermore, during the polishing phase, we provide the option to stain the concrete floors, allowing for a personalized design that reflects your taste.

- Polishing

- Grinding

- Burnishing

- Staining

We offer three extensive warranties for our flooring: the warranty, the manufacturer warranty, and the INSTALL warranty.

The Major Benefits of Concrete Polishing

Little-to-no downtime

After the polished concrete process is finished, the floors are ready for use right away, with no extra time needed for drying or curing. The team has effectively managed numerous projects without interrupting facility operations by carefully isolating and coordinating work on a section-by-section basis.

Cost-effectiveness

Opting for polished concrete can be a wise and economical choice, as it requires minimal material costs. With its low upkeep needs and durability, polished concrete proves to be a cost-effective and time-saving solution over time.

Slip resistance and safety

Although polished concrete floors may have a glossy appearance that gives the impression of being slippery, the polishing process actually enhances the natural slip resistance of the concrete when the surface is dry. Furthermore, the added brightness from polishing improves visibility.

FAQ's

Yes, polished concrete is highly durable and strong, making it an ideal choice for high-traffic areas like commercial kitchens and restaurants.

It is a dense, heavy floor typically requiring a minimum depth of 75mm to 100mm. Joints must be cut into the surface to control the concrete’s shrinkage. Due to its weight and thickness, installing this type of flooring can be challenging in residential settings.

In concrete polishing, several chemicals are used to enhance the process and the final result:

- Densifiers

- Hardeners

- Sealants

- Grinding and Polishing Compounds

- Concrete Cleaners

These chemicals work together to ensure that the polished concrete surface is durable, aesthetically pleasing, and easy to maintain.

To determine if polished concrete is right for your facility, consider its suitability for high-traffic areas due to its durability and resistance to wear. If you prefer a sleek, modern aesthetic, polished concrete offers a customizable, shiny surface. It’s also low maintenance, easy to clean, and highly durable, making it ideal for areas with heavy machinery. While the initial cost may be higher, the long-term maintenance is cheaper, and its eco-friendly nature adds value. Lastly, ensure your existing floor is sound and level, as this will impact installation. Assessing these factors will help you decide if polished concrete meets your facility’s needs.

Yes, you can add color to polished concrete.

Polishing concrete is a complex task that involves heavy machinery and specialized diamond tools, making it unsuitable for a DIY project. It’s best to hire a professional concrete polishing contractor like GP Concrete Polishing, who has the expertise and equipment to ensure the best results.

Yes, polished concrete is ideal for a variety of commercial environments, including offices, industrial settings, airports, retail stores, and educational facilities. Its durability and versatility make it a great choice for diverse commercial applications.