Industrial Polished Coatings Livonia, MI

Based in Detroit, MI, we’re dedicated to offering high-performance industrial polished coatings that are built to withstand the rigorous conditions found in warehouses, manufacturing plants, and various industrial environments. We understand the importance of having flooring that is not only durable but also safe and easy to maintain in these challenging settings.

Our skilled team employs state-of-the-art floor polishing and coating technologies to provide enduring solutions capable of handling heavy foot traffic, chemical spills, and demanding usage. We pride ourselves on delivering outstanding service and offer comprehensive cost estimates for every project we undertake.

Industrial polished coatings not only boost the durability and safety of your facility’s flooring but also enhance its visual appeal and simplify the cleaning process. We provide a diverse range of coating systems tailored to meet the specific demands of different industrial applications, including epoxy, polyurethane, and specialized chemical-resistant finishes.

Our knowledgeable professionals will evaluate your facility’s unique requirements and propose the most effective and budget-friendly coating options. As a highly regarded company within the community, we are dedicated to offering outstanding service and achieving results that endure over time.

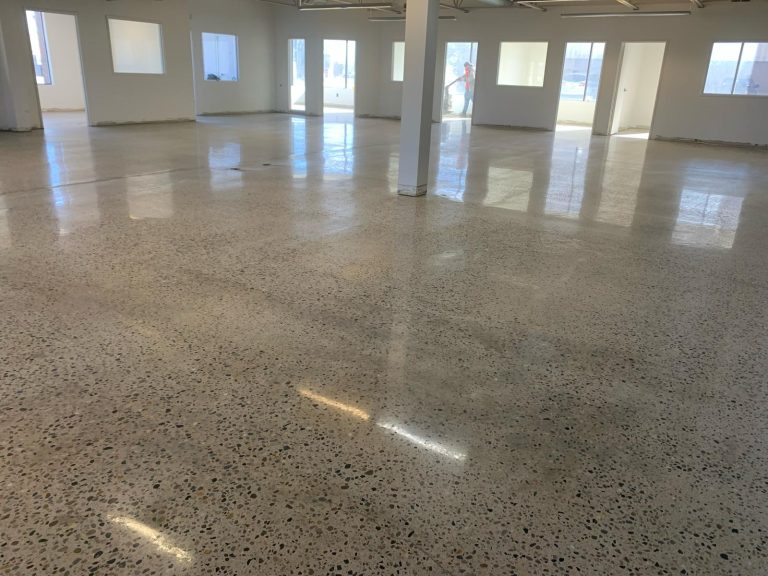

Industrial Polished Concrete Floors

Industrial polished concrete floors are a dependable and eco-friendly flooring solution for the vibrant industrial sectors in Detroit, MI. We specialize in transforming ordinary concrete slabs into high-quality, durable, and visually appealing surfaces that meet the demands of busy environments.

Utilizing advanced techniques, we grind, hone, and polish concrete to create a dense and tough flooring system with the aid of powerful floor polishers and diamond polishing methods. This meticulous process guarantees that your flooring can endure heavy loads and frequent usage, making it perfectly suited for industrial applications.

Opting for industrial polished concrete floors ensures a commitment to exceptional durability and remarkable resistance to wear and tear. Unlike conventional flooring alternatives, our polished concrete eliminates the need for waxes or additional coatings, which significantly lowers maintenance costs and reduces operational downtime.

Moreover, we offer the option to enhance your polished concrete floors with safety features like non-slip finishes and line striping. Our dedication to providing top-notch service ensures that we deliver long-lasting flooring solutions customized to meet the specific requirements of your industrial facility.

Industrial Floor Polishing

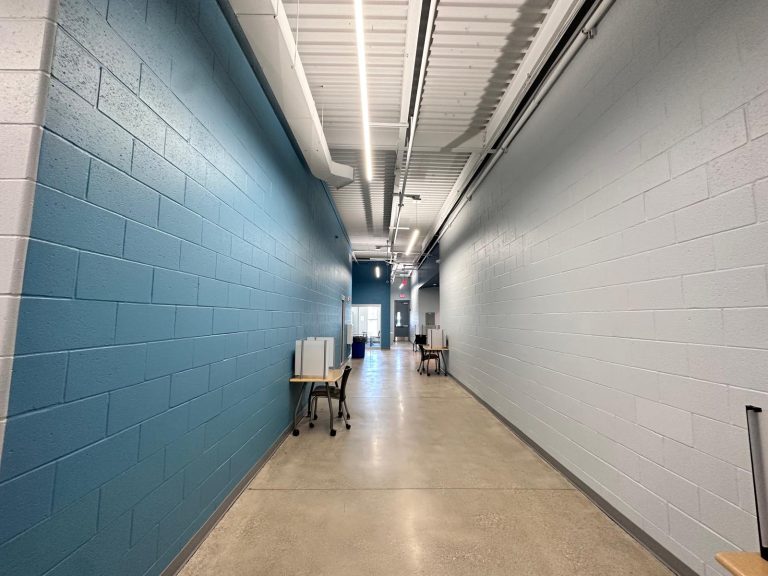

Our company focuses on providing industrial floor polishing services in Detroit, MI, designed to enhance the durability, safety, and aesthetic appeal of concrete floors in industrial environments. Our skilled professionals employ robust floor polishing equipment and innovative techniques to grind, hone, and achieve a high-gloss finish on concrete surfaces.

The polishing technique creates a dense, non-porous layer that is highly resistant to dust, stains, and general wear and tear, making it particularly suitable for rigorous industrial environments. We offer a full range of services, starting from the initial evaluation to the final buffing and sealing process, along with straightforward and transparent pricing.

Our industrial floor polishing solutions not only help lower maintenance costs but also enhance the overall safety and operational efficiency of your facility. The polished concrete surfaces are easy to maintain, minimizing dust and allergen buildup, which contributes to a healthier work atmosphere.

Furthermore, the reflective quality of polished concrete can improve ambient lighting in your space, leading to reduced energy usage. As a trusted service provider in your area, we are committed to offering exceptional service and customized flooring solutions to fulfill all your industrial needs.

Industrial Polished Concrete

Selecting the appropriate flooring for your workplace is essential for ensuring both safety and functionality for your employees. One excellent option to consider is industrial polished concrete floors. These floors are not only resilient but also low-maintenance, making them ideal for environments such as factories where heavy machinery is in operation. Our concrete floor polishing services cater to a wide range of facilities.

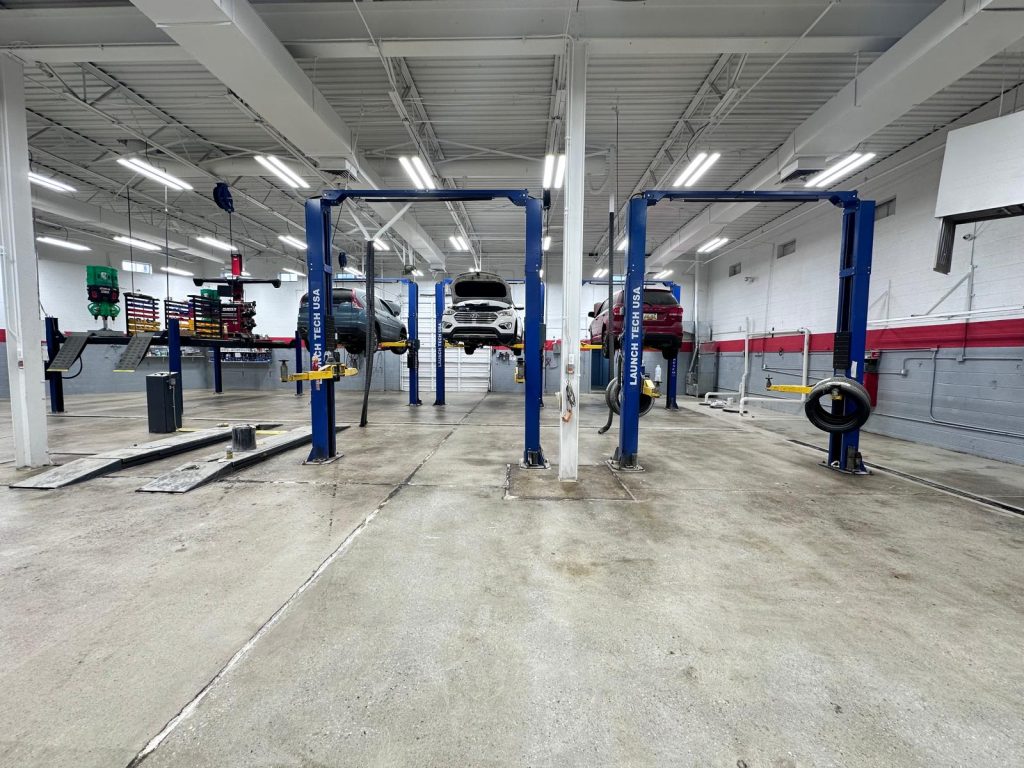

In industrial environments, the flooring must endure significant wear and tear, particularly from heavy equipment like forklifts. While conventional concrete may appear to be a viable choice, it tends to generate dust that can detract from the cleanliness and appearance of a warehouse or industrial space. To achieve durable and budget-friendly flooring solutions, it is important that they are waterproof and resistant to chemicals.

Otherwise, facilities may find themselves needing to replace their floors every few years. We offer outstanding flooring solutions designed specifically for industrial and manufacturing settings. Our offerings include polished concrete floors and high-quality industrial-grade epoxy floor coatings, both engineered for longevity and durability.

We offer a wide variety of industrial concrete flooring options. Don’t hesitate to reach out to us for more information!

Applications For Polished Concrete Flooring

Concrete flooring options are highly adaptable and particularly ideal for industrial environments and expansive manufacturing areas. They provide these sectors with aesthetically pleasing floors without the necessity of costly full concrete replacements. Often, processes such as resurfacing, leveling, and the application of epoxy coatings can adequately meet their needs. When evaluating different flooring materials, polished concrete emerges as a budget-friendly choice for industrial applications.

- Large manufacturing facilities

- Automotive assembly plants

- CNC machining industries

- Food & beverage industries

- Manufacturing facilities

- Pharmaceutical

- Laboratories

- and more.

In a standard industrial environment, our team is capable of polishing approximately 1,500 square feet of flooring each day. For larger spaces, we can deploy multiple teams to expedite the installation process. When considering the cost per square foot, polished concrete and industrial-grade epoxy floor coatings are quite affordable, with low ongoing maintenance costs. In fact, upkeep for polished concrete floors in an industrial setting is roughly 50% less than that of vinyl composition tile (VCT), which is often used in similar locations. If you’d like to receive a quote for installing polished concrete floors in your industrial facility, please contact us for a complimentary estimate.

Benefits Of Polished Concrete

Even though it has a straightforward name, polished concrete encompasses much more than merely adding a surface sheen or layer. According to concrete polishing experts, the process involves ten distinct steps that are akin to the techniques used in granite polishing. In industrial environments, achieving a polished concrete surface entails meticulously grinding down the concrete to produce a sleek and shiny appearance. This procedure leads to a denser, more durable surface, making dry concrete polishing particularly efficient for untreated concrete slabs typically found in industrial settings. The benefits of polished concrete include improved resistance to a range of challenges, such as

- Chemical spills

- Tire marks

- Heavy equipment markings

- Airborne dust and exposure to corrosive chemicals

- Impact damage from falling objects.

Contact us today to explore the flooring solutions that perfectly match your industry requirements, and get an accurate estimate for our concrete polishing services. Our industrial concrete coatings are designed to be resilient, making them perfect for areas with high foot traffic or where heavy machinery may affect the floors. Give us a call for your complimentary quote now.

Advantages Of Industrial Polished Concrete

Here are some of the key benefits of choosing polished concrete flooring for your industrial facility.

Durability And Longevity

Polished concrete boasts exceptional durability, capable of enduring significant foot traffic, heavy machinery, and equipment usage. Its resistance to spills, stains, and scratches makes it a low-maintenance choice for industrial environments.

Aesthetics

The sleek, high-gloss finish of polished concrete imparts a contemporary and sophisticated ambiance to any industrial setting. The surface can be stained or dyed in a myriad of colors and patterns, providing ample design versatility.

Cost-Effective

When compared to luxurious flooring options such as marble, granite, or terrazzo, polished concrete is a budget-friendly alternative. Its straightforward maintenance requirements also contribute to lower long-term expenses related to cleaning and care.

Eco-Friendly

Polished concrete is an eco-conscious flooring solution as it repurposes existing concrete slabs and minimizes the need for additional materials. Furthermore, it contributes to a lower carbon footprint by decreasing energy consumption during both manufacturing and transportation.

Slip-Resistance

To increase safety in high-traffic areas, industrial polished concrete can be treated with a specialized non-slip coating, providing extra grip for employees and customers alike.

Improved Indoor Air Quality

In contrast to many other flooring materials that may emit volatile organic compounds (VOCs) or harmful chemicals, polished concrete remains inert, releasing no harmful substances into the environment.

The Levels Of Polished Concrete: A Comprehensive Guide

Here’s how we carry out our 400 Grit Polish process:

- Remove any existing adhesives from the surface, including tile mastic and carpet glue.

- Repair and fill in any noticeable cracks as needed.

- Begin grinding the floor using diamond grits of 30, 80, and 120.

- Switch to 50 grit and grind the floor once more.

- Polish the surface with 100, 200, and finally 400 grit resins.

- Finish the procedure with the 400-grit resin bond to achieve a subtle low-sheen finish.

- This results in a matte appearance with minimal reflections visible from a distance of about 100 feet.

- Optionally, you can incorporate color and a densifier into the process.

- Carefully hand-polish the edges along the walls for precision.

- Apply two coats of sealer for added protection.

- Burnish the floor to achieve a glossy finish.

- This results in a soft matte look with a low-sheen effect.

Here’s how we execute the 800 Grit Polish process:

- We employ diamond abrasives rated at 800-grit or higher to create a finish that surpasses a level 2 sheen.

- The process begins with the removal of any residual adhesives, such as tile mastic or carpet glue, from the flooring.

- Next, we inspect and repair any cracks that need attention.

- We start by grinding the floor with 30-grit diamonds to improve the overall quality of the surface.

- This initial step is followed by additional grinding using 80-grit and 120-grit diamonds for further refinement.

- We then proceed to polish the floor with a series of resin grits: 50, 100, 200, 400, and finally, 800 grit to ensure a flawless finish.

- This method yields excellent light reflectivity, allowing for clear reflections of side and overhead lighting that can be seen from 30 to 50 feet away.

- As an optional enhancement, we can apply color and densifier to improve both the look and durability of the surface.

- To add a meticulous touch, we hand-polish the edges along the walls.

- We conclude the process by applying two coats of sealer.

- Finally, we burnish the floor to create a glossy, visually striking finish.

- The end result is a surface that boasts a significantly enhanced sheen and improved light reflectivity.

Here’s our comprehensive guide to achieving a 1500 Grit Polish:

- We start by utilizing resin pads rated at 1500 grit or higher to improve surface quality.

- First, we remove any adhesives present, such as tile mastic or carpet glue.

- Next, we identify and repair any cracks that need attention.

- The process begins with grinding the floor using 30-grit diamond abrasives to prepare the surface.

- We then advance the grinding stage with 120-grit diamonds for additional refinement.

- Polishing the floor follows a systematic approach with 200, 400, 800, and ultimately 1500 grit resin pads to achieve a polished appearance.

- This method enhances the floor’s shine and clarity, resulting in a semi-polished finish.

- Additionally, we have the option to add color and a densifier to boost both appearance and durability.

- For a precise finish, we hand-polish the edges along the walls.

- Subsequently, we apply two coats of sealer to safeguard the surface.

- Finally, we burnish the floor to achieve a glossy and attractive finish.

- Reflections on the surface will be clearer and sharper, although not as distinct as those produced with higher grit levels.

Here’s our 3000 Grit Polish process:

- We begin by utilizing either 3000-grit resin-bond diamond pads or a high-speed burnisher paired with specialized buffing pads.

- Initially, we eliminate any existing adhesives, including carpet glue and tile mastic.

- Next, we address and repair any cracks present in the surface.

- The grinding process is done using diamond grits, starting at 200.

- We then polish the floor with resins in increments of 400, 800, 1500, and culminating in 3000 grit to achieve a silky finish.

- This process results in a glass-like, mirror finish.

- The surface will exhibit a high level of shine and clarity, providing sharp reflections of surrounding objects.

- As an optional step, we can apply a color treatment and densifier. We also meticulously hand-polish the edges of the walls for precise detailing.

- From different angles, the floor gives the impression of being wet.

- We then apply two coats of sealer.

- The final touch involves burnishing the floor to enhance the glossy appearance.

- Completing the polishing process ensures the surface achieves optimal gloss and smoothness.

- Concrete is refined using specialized grinding equipment to eliminate any imperfections.

- Should it be necessary, any cracks or flaws are addressed with an appropriate patching material.

- Further grinding with finer diamond tools may be performed based on the desired finish and the condition of the flooring.

- After the grinding process is finished, the surface is thoroughly cleaned.

- If preferred, a stain can be applied, offering a variety of options from subtle neutral tones to vibrant colors.

- The surface is then coated with a sealer tailored to the specific requirements of the project and the goals for the floor, with additional layers applied for softer or more porous concrete.

- The grind, stain, and seal technique is quicker than conventional mechanical polishing methods.

- We start by utilizing our industrial diamond grinder to effectively grind the surface, ensuring that enough of the top layer is removed for optimal sealer adhesion.

- Our goal is to eliminate the old, unsightly surface, exposing a fresh and clean foundation that is primed for staining and sealing.

- We offer a range of sealer options customized for the specific location and use of the floor. If you opt for staining, we first apply the stain and then finish with a sealing coat.

- Explore our online collection of stain colors available for your selection.

- It is important to note that skipping the refinement phase with higher diamond counts may lead to noticeable swirls, which is a trade-off for reducing time and costs.

FAQ's

Polishing concrete floors involves a detailed, multi-step approach that demands both patience and precision to achieve the desired outcome. Our comprehensive 7-step process provides a clear guide to the technique of polishing concrete floors.

- Remove existing flooring

- Make sure the floors are level, and any cracks are repaired.

- Grind the concrete flooring using a variety of metal-bonded diamond grits.

- Apply a chemical hardener to strengthen and densify the concrete.

- Start polishing the concrete using a resin-bonded diamond.

- Gradually increase the grit level until you achieve the desired sheen.

- Apply a high-quality sealant to protect the concrete and make it easy to maintain.

In concrete polishing, several chemicals are used to enhance the process and final results:

- Densifiers

- Sealers

- Concrete Cleaners

- Conditioners

These chemicals work together to achieve a polished, durable, and aesthetically pleasing concrete floor.

Polished concrete can be pricey for several reasons. First, the process involves multiple steps, including grinding the surface to remove imperfections, applying a densifier to harden the concrete, and then polishing it to achieve a smooth, shiny finish. Each of these steps requires specialized equipment and materials. Additionally, the quality of the final product depends heavily on the skill and experience of the contractors. Labor costs can also be significant, as the process is time-consuming and labor-intensive.

Polished concrete can significantly enhance the look of an industrial facility. It provides a sleek, modern, and high-end appearance that can elevate the aesthetics of the space. Here are a few specific impacts:

- Reflective Finish

- Uniformity

- Color and Design Options

- Low Maintenance

- Durability

The cost of industrial polished concrete flooring depends on several factors. Larger floors tend to be more cost-effective per square foot because larger sections can be worked on at once, reducing overall labor time. However, repairing damaged concrete can increase costs due to the extra labor and materials required to properly prepare the surface. Prices generally range from $3 to $6 per square foot, depending on variables like the total area, how the space is divided, and whether the floor has an existing coating or tile that needs removal.

The duration of an industrial concrete polishing project depends on several factors, including the condition of the concrete, the size of the area, the level of polish required, and the type of equipment used. Generally, for a large industrial space, the process can take anywhere from a few days to weeks. A typical process includes surface preparation, grinding, honing, and polishing, followed by the application of a sealer if needed. For precise estimates, it’s best to consult with a contractor who can assess your specific project needs and provide a detailed timeline.

Polished concrete is commonly used in various settings such as retail stores, restaurants, warehouses, manufacturing facilities, healthcare and educational institutions, office buildings, airports, shopping malls, showrooms, exhibition halls, museums, galleries, and other high-traffic public spaces.

Following are the advantages of polished concrete

- Affordable

- Durable

- Lasting

- Low-maintenance

- Environmentally friendly

- Non-slip

- Reflective

- Customizable